Chemical Earthing is one of the most trending and amazing topics in Electrician Life. When you are thinking about earthing then you have to predict some questions. On those questions, you have also looked at Chemical Earthing Questions. So, here we are getting all the important information about Chemical Earthing.

We discuss the following things on this Chemical Earthing process that are as follow:

- What is Chemical Earthing

- Chemical Earth Pit

- Chemical Earthing Electrode

- Chemical Earthing Electrode Size

- Chemical Earthing Compound

- Chemical Earthing Drawing

- Chemical Earthing Material

- Chemical Earthing Rod Price List

So, these are some things about the chemical earthing. We are trying to understand everything about these things. I hope you are interested in this topic because we share the full information with amazing graphics about this Chemical Earthing Manufacturing Process.

Table of Content

What is Chemical Earthing

Chemical Earthing is a branch of Electrical Earthing where we use chemical powder, coal, and salt material. In this chemical earthing we do not use only coal and salt material but we use chemical powder.

In a general earthing sense, We put salt and coal material on the electrode. But Chemical Earthing do not do that function. We put Chemical Powder on the Chemical Earthing. There are two types of chemical powder used in Chemical Earthing. Now you know which chemical is used in chemical earthing.

- Carbon Powder

- Bentonite Powder

Carbon Powder is black color powder whereas bentonite powder is brown in color. The use of Carbon Powder in normal places but bentonite powder is used in dry places.

Where do we use Chemical Earthing?

If we want to use chemical earthing, then we can also use chemical earthing at home places, but there are some places where only chemical earthing should be done. In the hilly area chemical earthing will be done.

In general, then we use chemicals earthing the moisture places. But in some cases, the chemical earthing does not support the various types of places.

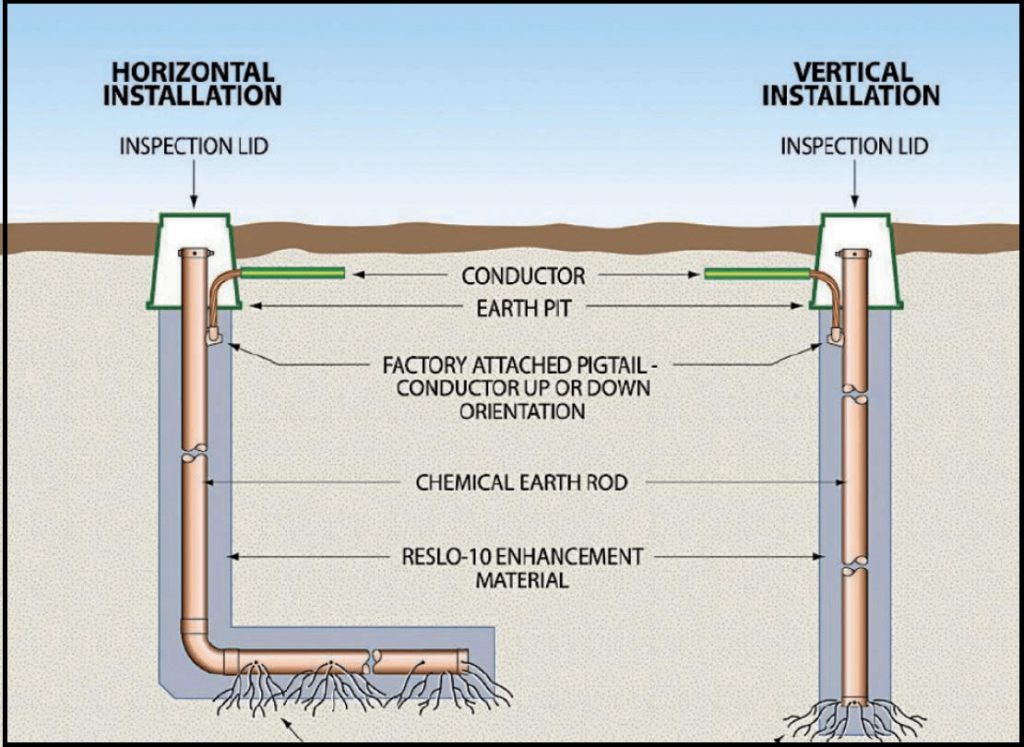

Chemical Earth Pit

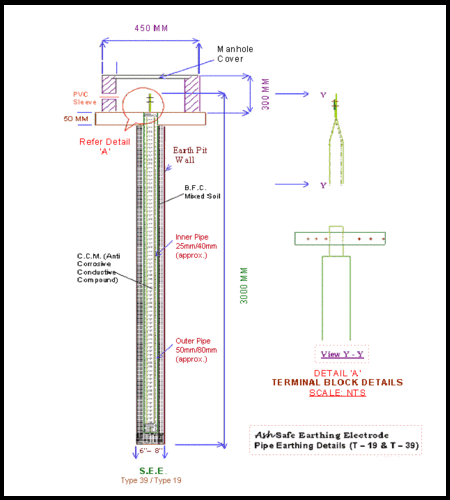

Chemical EarthPit is also another name for Chemical Earthing. To make the Chemical Earth Pit you need to follow some terms and conditions as follows:

- Make an EarthPit 500*500*200 mm.

- Make a hole with a center of 100mm diameter and 3.5 m depth.

- Use 25 Kg of Chemical Powder with Water.

- Wait for 6 to 10 hours.

- Place the electrode in the hole at an upright position till the end to top manners.

- Fill the chemical earth pit with chemical compounds and water absorption.

- Make sure to complete the chemical earth pit connection and soil resistivity.

Difference Between Normal Earthing vs Chemical Earthing

There is no more difference between normal earthing and chemical earthing. There is little difference between normal earthing and Chemical Earthing.

| Normal Earthing | Chemical Earthing |

| In normal Earthing, we use salt and coal. | In Chemical Earthing, We use Compound powder or a chemical powder. |

| Use normal earthing in normal places. | Use Chemical Earthing in hilly areas or stony areas. |

| Require Regular Maintenance. | Maintenance Free. |

| More Fluctuation in OHMIC Value. | No Fluctuation of Current in OHMIC Value. |

| More area and space required | Less area and space are required. |

| GI Pipe with Funnel and Hole | Double Pipe with flat technology. |

Additional Read: Copper Plate Earthing

So, this is the difference between normal earthing and chemical earthing. Now we are moving to our next topic.

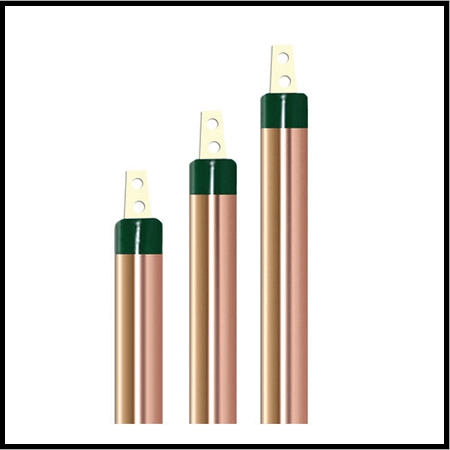

Chemical Earthing Electrode

Chemical Earthing Electrode is a type of GI Pipe. Now we understand how to make chemical earthing electrodes. Inside the Chemical Earthing Electrode is completely filled with Chemicals. In Chemical Earthing electrode has a terminal on the top side that exits the two holes.

- Chemical Earthing Electrode is Maintenance Free.

- Completely filled with Chemicals

- 5 Feet Long in Size

- Having the terminal at the top.

Chemical Earthing Electrode Size & Specifications

Now here we are discussing the Chemical Earthing Electrode Size. The Chemical Earthing Electrode following size is mentioned below the table.

| Material | Copper Chemical Earthing Electrode, Galvanized Iron (GI) |

| Diameter | 25mm to 80mm |

| Length of Electrode | 1 meter to 6-meter |

| Size of Conductor | (25×3)mm,(25×6)mm, (30×6)mm, and (40×6)mm |

| Type of Earthing | Sealed maintenance-free chemical-filled earthing electrode. |

| Ground enrichment material | Minimum 25 Kg |

So, this is the Chemical Earthing electrode size. Now we are discussing the chemical earthing material.

Chemical Earthing Material

Chemical Earthing is the most economical and efficient method with maintenance-free. So, there are different types of materials used in chemical earthing. The chemical earthing material is as follows:

- Chemical Earthing Electrode

- Water

- Wire Mesh Connectors

- Funnel

- Ground enrichment Nut

- Carbon Powder or Bentonite Powder

- SWG Copper Wire

- Socket

- Below Cover

- Telescopic Cover

- Chemical Earthing Rod

- Guideway wiper

So, these are the different types of materials that we used in the chemical earthing.

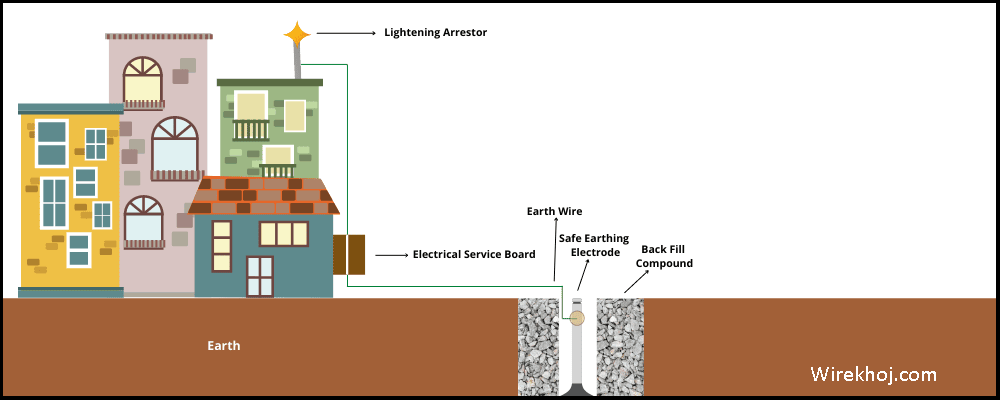

Chemical Earthing Drawing or Diagram

Now we are trying to understand the chemical earthing drawing or diagram. This is very quite simple. The chemical earthing drawing or diagram is given below the image.

Chemical Earthing Compound

When we are doing the chemical earthing then we need these two types of chemical earthing compounds that are as follows:

- Bentonite Compound

- Marcionite Compound

These two types of compounds. You can select one compound and what compound you have to choose. The cost of the Bentonite compound is very low at a price of 600 Rs. to 800 Rs. And it comes in 50 Kg in weight.

Additional Read: Pipe Earthing

If you want to buy the Marcionite then the cost is very high, approximately Rs 6000 to Rs. 8000 in 50 Kg of weight.

How to install chemical earthing

To make chemical earthing, make a 6ft deep hole of diameter 10 inches. You will have to deepen the pit according to the length of your electrode. Insert the electrode inside the pit. Keep in mind that the terminal should be straight as above. Because we make the connection of wire and cable easily.

Now you have to connect the earth wire with the earthing electrode. Fill the earth pit with Ground Enhance compound and water. Making the mixture of Ground Enhance Compound and water is correct manners. So, this will reduce the earth’s resistance.

Now using this method the chemical earthing is fully completed. If you want to use this chemical earthing then, wait for 48 to 72 hours. After that, you can easily use your chemical earthing. So, this is the installation process of the chemical earthing.

Chemical Earthing Advantages & Benefits

So, guys, there are the different types of advantages and benefits of chemical earthing. These advantages and benefits are as follows:

Maintenance Free

This is a maintenance-free earthing, with no need for extra water pouring at regular intervals as in conventional earthing because it retains the moisture for a longer period.

Consistency

Constantlysustains the same land resistance value with the timing however of soil weather conditions. Unlike a standard copperplate/rod, the stability of the ACE chem rod will remain constant over the lifespan of the plat/rod, and the resistance of the electrode is less affected by climate conditions.

More Surface Area

The conductive compound creates a conductive zone, which provides the increased surface area for peak current dissipation and also gets a stable reference point.

- Adequate galvanization, highly conductive

- Corrosion-free, Eco-Friendly

- Low Earth Resistance, Carriers’ high peak current repeatedly

- A long and reliable life

Easy Installation

- Can be installed indoors or outdoors and in almost all soil conditions. Existing or new facilities require less space and time.

- As per IS:3043-1947 Requirements.

- ACE chemrod can be used as Biopod, Tripod, Quadapod, etc. Using one is a more linear/ring chemrod configuration, duly interconnected for the highly sensitive projects and wherever low OHMIC value is required.

Chemical Earthing Features

- Protects personal and sensitive equipment

- Dissipates lightning strikes

- Discharges short circuit currents.

- Prevents damage from powder and switching surges

- Provides stable reference.

Cost of Chemical Earthing

Chemical Earthing cost relies upon the different types of factors. Suppose, if you are doing electrical chemical earthing yourself then the expenditure will decrease.

But in case you use the Ground enrichment Pipe then the expenditure also decreases otherwise it will be the cost of rupees two thousand to three thousand.

Also if you use bentonite powder then the cost is Rs. 600 to Rs. 800. Whereas Marcionite Powder price is Rs. 6000 to Rs. 8000.

Chemical Earthing Rod Price List

Now here we are discussing the chemical earthing Rod Pricelist or Chemical Earthing Kit price list. The Chemical Rod Pricelist is as follows:

| Chemical Earthing Rod Name | Chemical Earthing Rod Price |

| Earthway GI + Copper Rod | Rs. 1350 |

| Earthway Copper Bonded | Rs. 730 |

| E-Daman GI Electrode | Rs. 1380 |

| Shri Surya Chemical Filled Electrode | Rs. 380 |

So, these are the chemical earthing rod prices. If you want to purchase that then you can purchase from the table below “Buy Now Link”.

Conclusion

In this article, we discuss everything about the chemical earthing, material, diagram, compound, installation, and advantages & benefits, etc.

So, guys if you like this article and enjoyed it then please share this blog post with your friends and families. If you have any query regarding this article then please contact with us.